HTOL - High Temperature Operating Life Test

JEDEC Standard: JESD22-A108F (July 2017)

JEDEC Standard: JESD22-A108F (July 2017)High Temperature Operating Life Test (HTOL) is performed to ensure the reliability of a semiconductor device under operation over the lifespan of the device.

Typically HTOL will be run at 125°C for 1000 hours with a 168 hour readpoint. Readpoints can, of course, be scheduled for any time during the test and 48 and 500 hour readpoints are not uncommon.

For a typical qualification the sample size required to pass qualification would be 3 separate lots of 77 devices. In reality most companies would run more than this amount to account for any potential issues due to handling damage, lost devices etc. Having to restart a 6 week test due to a simple human error is never a good place to be. The three lots of devices cannot be run through fab sequentially. i.e The line must be switched to a diffent product between lots. Many companies will specify a standard time interval between the qual lots.

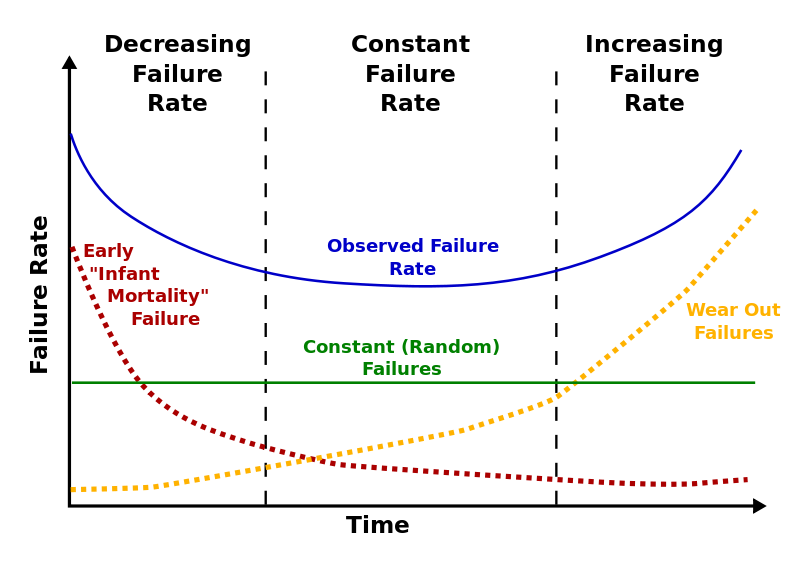

The bathtub curve shown here is well known in reliability engineering and is particularly relevant to HTOL. The early 48 and/or 168 hour readpoints are looking for any Infant Mortality Failures, which could indicate potential issues early on in the devices lifespan, particularly during the end products warranty period. The 1000 hour readpoint is to ensure that wear out failures do not begin to creep in during the required lifespan of the device.